In addition to the wide range of Zanolli ovens pizza, cooks can have auxiliary machines at their side that enable increased productivity even in a smaller workspace.

The new version of the heated disc press Zanolli Devil has winning characteristics: cast iron discs with thick chrome, a new safety system and a new edge forming system.

Let’s look in detail at the functioning, benefits, and refinements to use it best.

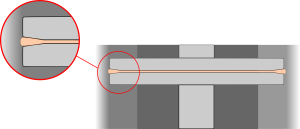

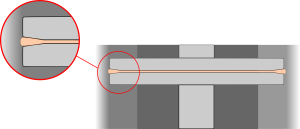

The crust is shaped thanks to the lower thickness of the outer part of both disks. The amount of dough that is pressed is therefore greater: the crust is served! Be careful though: there are two models of former, for 45 cm and 30 cm round pizzas. If the operator uses the 45 cm model to press a dough ball for a 30 cm round pizza, the crust will most likely not appear.

The non-stick cast iron disc may ensure optimal heat exchange; thick chrome also makes the surfaces more resistant to scratches during normal use.

The control panel allows you to adjust the thickness, disc temperature and pressure time. The operator must use both hands, limiting the risk of hands in dangerous positions inside the discs.

Of course, each dough has its own characteristics and the user must occasionally reset the parameters accordingly. We suggest at least 3 to 4 hours to bring the dough to room temperature. Pressure time varies with the hydration level. At a recommended temperature of 150°C, the pressure time can go from 2 seconds for soft dough to 1 second for less hydrated dough.

We recommend bearing in mind that hotter discs slightly precook, making the dough a bit less elastic.

The Zanolli Devil is a valuable aid to quickly prepare regular shape bases that develop the inevitable edge.

In addition to the wide range of Zanolli ovens pizza, cooks can have auxiliary machines at their side that enable increased productivity even in a smaller workspace.

The new version of the heated disc press Zanolli Devil has winning characteristics: cast iron discs with thick chrome, a new safety system and a new edge forming system.

Let’s look in detail at the functioning, benefits, and refinements to use it best.

The crust is shaped thanks to the lower thickness of the outer part of both disks. The amount of dough that is pressed is therefore greater: the crust is served! Be careful though: there are two models of former, for 45 cm and 30 cm round pizzas. If the operator uses the 45 cm model to press a dough ball for a 30 cm round pizza, the crust will most likely not appear.

The non-stick cast iron disc may ensure optimal heat exchange; thick chrome also makes the surfaces more resistant to scratches during normal use.

The control panel allows you to adjust the thickness, disc temperature and pressure time. The operator must use both hands, limiting the risk of hands in dangerous positions inside the discs.

Of course, each dough has its own characteristics and the user must occasionally reset the parameters accordingly. We suggest at least 3 to 4 hours to bring the dough to room temperature. Pressure time varies with the hydration level. At a recommended temperature of 150°C, the pressure time can go from 2 seconds for soft dough to 1 second for less hydrated dough.

We recommend bearing in mind that hotter discs slightly precook, making the dough a bit less elastic.

The Zanolli Devil is a valuable aid to quickly prepare regular shape bases that develop the inevitable edge.

You might also be interested in...